ch40n1k

Member

Hi folks,

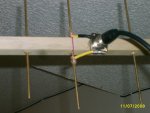

I've used several of the posts on this forum to construct an 800MHz yagi. I'm hoping some of you can help me out by letting me know if everything looks ok. The antenna seems to work fine, I just want to make sure I've constructed it correctly.

1.) I used a 36" wooden boom.

2.) I used 1/8" brass brazing rods for the elements.

3.) The driven element is cut in half, and each half is separated from the other on opposite sides of the boom.

4.) I used hot glue to secure the elements.

5.) Instead of connecting the coax directly to the driven element, I used a PL-259 post from Radio Shack. I soldered 12 gauge copper wire to the center conductor of the connector. I then connected a 12 gauge copper wire to the post itself with a brass bolt and nut. I then connected the center conductor wire to one half of the driven element, and the post connected wire to the other half of the driven element.

Will this method of connecting the coax to the antenna work ok? I've used this method with other antennas I've built in the past, and it seemed to work just fine.

Any help would be greatly appreciated. Thanks!

I've used several of the posts on this forum to construct an 800MHz yagi. I'm hoping some of you can help me out by letting me know if everything looks ok. The antenna seems to work fine, I just want to make sure I've constructed it correctly.

1.) I used a 36" wooden boom.

2.) I used 1/8" brass brazing rods for the elements.

3.) The driven element is cut in half, and each half is separated from the other on opposite sides of the boom.

4.) I used hot glue to secure the elements.

5.) Instead of connecting the coax directly to the driven element, I used a PL-259 post from Radio Shack. I soldered 12 gauge copper wire to the center conductor of the connector. I then connected a 12 gauge copper wire to the post itself with a brass bolt and nut. I then connected the center conductor wire to one half of the driven element, and the post connected wire to the other half of the driven element.

Will this method of connecting the coax to the antenna work ok? I've used this method with other antennas I've built in the past, and it seemed to work just fine.

Any help would be greatly appreciated. Thanks!

Attachments

Last edited: