For the antenna experts.

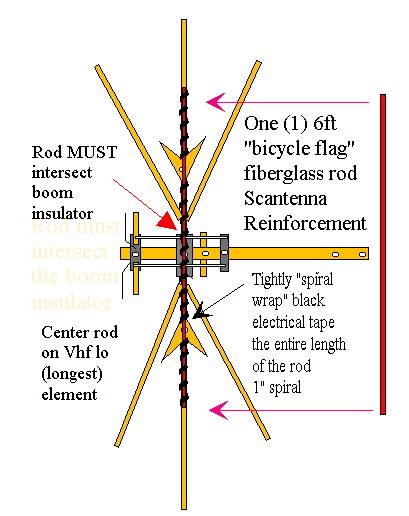

The scantenna's elements were made of hollow rolled tubing. Mine suffered a broken leg during Hurricane Sandy and I am going to repair it. I wanted to know, if one element is solid aluminum rod, or aluminum tubing that's a different thickness (same outside diameter), and the original is hollow rolled tube, will that have any effect on receive performance?

The scantenna's elements were made of hollow rolled tubing. Mine suffered a broken leg during Hurricane Sandy and I am going to repair it. I wanted to know, if one element is solid aluminum rod, or aluminum tubing that's a different thickness (same outside diameter), and the original is hollow rolled tube, will that have any effect on receive performance?