Couple of things I'd add:

Don't buy the cheapest crimp terminals you can find. The cheap ones have a very thin tin coating that will come off and you'll get corrosion. Get some good name brand crimp connectors that are:

-Ring terminal the correct size to fit over that stud.

-Correct size for the wire gauge.

This is important if you want a good low resistance connection (and you do….)

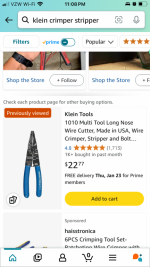

Get the right crimpers. With respect to Chris above, do -not- buy those kind. They usually do a poor job of crimping. Go to Home Depot and purchase these:

Ensure uniform crimp for your electrical wiring tasks by choosing this highly durable Klein Tools Ratcheting Crimper. Comes with easy mechanism.

www.homedepot.com

Those are a 'full cycle' tool. They'll do a nice wide crimp on the terminal, and the handles will not release until it's been fully cycled. They cost a few more bucks than the ones posted above, but it's worth every additional cent. I've been using different variations of those for about 30 years now and never had a crimp fail.

Following up with some

marine grade heat shrink tubing isn't a bad idea. Make sure it's the marine grade stuff. It has a hot melt adhesive on the inside that will flow when heated and seal the connection. It keeps water out and acts as a strain relief.

If you upsize your conductors, as the green one said above, you'll need to make sure you have the right size terminals and crimpers to do it right.

For your negative, ground it close to the radio.