Hi All,

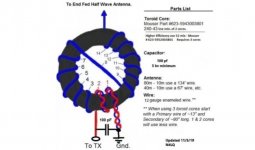

I have an 80-10m EFHW in an inverted V format with a 49:1 unun that I built myself (not from a kit). I designed it to handle high power (1.5-2kW) and was my first ever build and first ever EFHW. It consists of three stacked FT240-61 toroids wrapped with 12G enameled copper wire and a 10kV 100 pF capacitor between the center conductor and ground to help with SWR on 17-10m.

This antenna has performed very well on all bands (phone and digital), so far, and have received good reports on signal strength. However, after a recent rain (maybe it's a coincidence), I have been encountering an issue on 17-10m where the SWR will quickly climb when transmitting barefoot at 75-100W. Thinking that I had water intrusion somewhere, I checked the outside connections and unun. All dry. I did observe that the capacitor was getting very hot, measuring near 150°F at one point. All other components in the unun remained cool. This may be what is causing the SWR to climb. I replaced the capacitor like-for-like and observed the same thing. How can I resolve this, short of immersing the capacitor in a small bath of mineral oil? Or, is this a performance characteristic of an EFHW?

Regards,

-Justin (NO6GN)

I have an 80-10m EFHW in an inverted V format with a 49:1 unun that I built myself (not from a kit). I designed it to handle high power (1.5-2kW) and was my first ever build and first ever EFHW. It consists of three stacked FT240-61 toroids wrapped with 12G enameled copper wire and a 10kV 100 pF capacitor between the center conductor and ground to help with SWR on 17-10m.

This antenna has performed very well on all bands (phone and digital), so far, and have received good reports on signal strength. However, after a recent rain (maybe it's a coincidence), I have been encountering an issue on 17-10m where the SWR will quickly climb when transmitting barefoot at 75-100W. Thinking that I had water intrusion somewhere, I checked the outside connections and unun. All dry. I did observe that the capacitor was getting very hot, measuring near 150°F at one point. All other components in the unun remained cool. This may be what is causing the SWR to climb. I replaced the capacitor like-for-like and observed the same thing. How can I resolve this, short of immersing the capacitor in a small bath of mineral oil? Or, is this a performance characteristic of an EFHW?

Regards,

-Justin (NO6GN)