"One option is to use a fork terminal on the positive wire. Tuck it under the existing nut.

If that is not going to work, then drilling a hole and tapping it, or at least a nut, bolt and washers is a good option."

No, the nut will not offer any gap whatsoever between it and the clamp-block. In addition, the peened stud keeps any additional nut from threading over it.

Over the years, my work history included several trades and skills. However, my main “fallback trade” and expertise was as a machinist, (1st class Job shop 23+ years). I’ve seen just about every kind of thread and thread style you can imagine, including the interference method used on this 6mm stud.

They distort a section of the threads using one of any number of various techniques to keep a normally threaded nut from threading past a given section in the stud, (or an additional nut from threading on it, as is the case here).

This method (peening or dimpling) is a fast and cheap way to create an interference thread. It’s used in non-critical applications but for larger fasteners and more important applications, a far more precise technique is used.

"Now if we can just get you to see the light on antenna installs, we'll have fully converted you over to our side."

LOL, you have a better chance of convincing me to sprout wings and fly than you do in trying to get me to drill a hole any larger than 1/32" (the size of the hole I drilled in the battery box) into the body of that $60K Jeep! I looked at hood-clamp antennas but the risk of bending the metal at the clamping area was too great.

Besides, the SR A-10 Mag-Base that Stryker makes today comes with an RG8X coax. I know of the the direct-mounted antennas and the better results, but the ground plane of the A-10 is quite sufficient for CB mobile. W/O skip, I regularly get out between 10 and 20 miles, no problem.

When you consider that the roof of the 2022 Jeep, (with 22" Tires), is 6'7" and the A-10's whip is another 5 feet, (not counting the 7.5" base), it's over 11.5 feet high.

I don't need convincing that there are better antennae and mounting methods for mobile, I'm already well aware of that. Way back in my early CB years, (circa 1974), on through to my OTR/48 truck driving years, (1990-1996), I picked up a lot about increased efficiency via antennas.

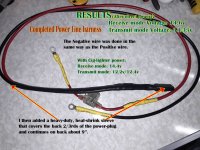

I even knew it was better to make a direct power connection for the radio way back then. It's like you said about "quick" being the go-to method more often than not. However, I must admit that I was surprised at how much more improved the direct power connection was! I only expected (and dared hoped for) about a 1 volt improvement, so yes, this direct power was definitely worth the effort.

But the A-10 serves its purpose well. Keep in mind that I bought the Jeep new, less than a year ago and it hasn't even got 1700 miles on it. If I ever get around to earning a Ham operator license (and that's a very real possibility), and I get a "big radio", I'll very likely go with a much better antenna rig.

Perhaps more importantly is the fact that I can easily unscrew the A-10's coil, cap off the threaded receiver with the cap Stryker included with the antenna, (which has an O-Ring seal), and go through the car wash.

Then, when I screw the coil back on the receiver in the mag-base, the SWR is right where it was before. No retuning!

So to recap; 11.5+ feet high, Easy to disconnect/reconnect w/o SWR loss or retuning, RG8X coax, and most importantly, NO HOLES. You have to admit Mmckenna, those are pretty good reasons for sticking with the A-10, no?

Rich

PS Thanks for the help and encouragement!