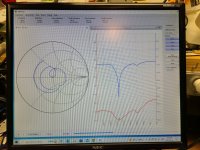

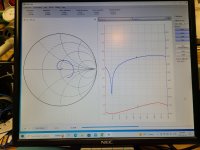

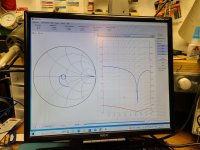

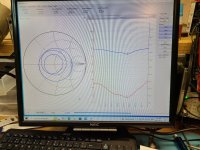

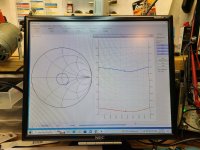

I have verified the longer elements and am satisfied I am on the right track to getting this antenna tuned see pictures 1 to 3. the difference between picture 2 and 3 is .5mm filed off elements. I worked all last Sunday trying to phase the polarizations together to no avail. The gamma match is so incredibly sensitive and trying to get both of them aligned in unison I could not accomplish. I would get close then make a wrong move and would have to start over. It seems to be 100ths of a mm that these would need equal. I turned the lights off late Sunday.

I am not sure Joel how one would deal with environmental conditions. I wonder how SKA in Australia would deal with morning dew and frigid night temperatures to desert heat in the day or how the 500m dish in China would deal with their unique weather conditions. I agree some form of variable length transmission line to fine tune would be ideal and have been thinking about how to achieve this. If radio waves can travel through rain, fog the atmosphere and stellar dust. How much impact does humidity have? An interesting question.

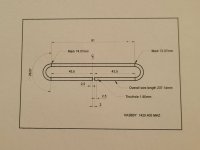

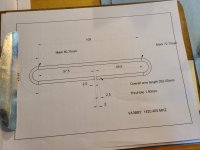

Today I made a short test antenna so I can develope a folded dipole to work with this array. I don't see any other way to match these antennas reliably. Gamma is way to sensitive with 2 polarizations and next to impossible to match together and what happens if one gets bumped by a fat bumble bee or hit with a hail stone or even bird sh_t? I have made a new mechanical bender that utilizes a sealed bearing to make the 180 degree turn repeatable and will share pictures maybe tomorrow and also what I have come up with to solder the coax to the aluminum dipole element. This development is going to take dozens of attempts to get the correct overall length, there is no adjustment in these so trial and error until it is right. Tomorrow morning I will generate a CAD drawing for reference points to use with this bender and an initial overall length to try.

Also today for interest, I wanted to see how much temperature affects elements of these lengths and diameters. Picture 4 is a element cut to length in my basement shop which is a very constant 17 degrees Celsius. Picture 5 is the same element put in front of a heater I use to accelerate epoxy cure times. This element was hot when I measured it, at least 40 degrees Celsius. I then put the whole finished and antenna in one of my freezers for several hours while I was working the bender. I have a thermometer in it and it reads -20 Celsius. Picture 6 shows the same element being measured directly after coming out. Interesting results but don't know how much impact at this frequency it would have.

Thanks,

I am not sure Joel how one would deal with environmental conditions. I wonder how SKA in Australia would deal with morning dew and frigid night temperatures to desert heat in the day or how the 500m dish in China would deal with their unique weather conditions. I agree some form of variable length transmission line to fine tune would be ideal and have been thinking about how to achieve this. If radio waves can travel through rain, fog the atmosphere and stellar dust. How much impact does humidity have? An interesting question.

Today I made a short test antenna so I can develope a folded dipole to work with this array. I don't see any other way to match these antennas reliably. Gamma is way to sensitive with 2 polarizations and next to impossible to match together and what happens if one gets bumped by a fat bumble bee or hit with a hail stone or even bird sh_t? I have made a new mechanical bender that utilizes a sealed bearing to make the 180 degree turn repeatable and will share pictures maybe tomorrow and also what I have come up with to solder the coax to the aluminum dipole element. This development is going to take dozens of attempts to get the correct overall length, there is no adjustment in these so trial and error until it is right. Tomorrow morning I will generate a CAD drawing for reference points to use with this bender and an initial overall length to try.

Also today for interest, I wanted to see how much temperature affects elements of these lengths and diameters. Picture 4 is a element cut to length in my basement shop which is a very constant 17 degrees Celsius. Picture 5 is the same element put in front of a heater I use to accelerate epoxy cure times. This element was hot when I measured it, at least 40 degrees Celsius. I then put the whole finished and antenna in one of my freezers for several hours while I was working the bender. I have a thermometer in it and it reads -20 Celsius. Picture 6 shows the same element being measured directly after coming out. Interesting results but don't know how much impact at this frequency it would have.

Thanks,