Lots of great points and questions....

The first is that the velocity factor is a rough planning factor, it varies a lot, from roll to roll and according to some, foot by foot.

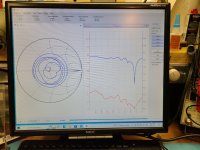

One of your points did open an old can of worms in my head.... some people really like measuring things based on resonant frequency, I have to assume because they want to control SWR or dont have better test equipment for other tests... The other way of measuring is "phasing" ie 90 degrees at 1.5 Ghz or something, this is good if you want to put something into quadrature to make a measurement.... The best (to me) idea is to use the actual time delay of a line, this is how they (them?) make wideband phased arrays, the swr and everything else will be off, but wide-banding things is sometimes more important... If you look at the wullenweber description, it was supposed to work from 1 Mhz to 30 Mhz with very high accuracy.... measuring and cutting things for SWR or Phase delay just wouldn't work (too broadband).

The part about your post that will get most people annoyed, is that after measuring the cable with the connectors on, and you need to cut it, you have to take the connector off, cut it, and (in my case) re-install the same connector, if you are using N connectors there is a rubber gasket that breaks when you put it on the first time, so you loose a little waterproofing when it's redone, but it would be ridiculous

s to use a new connector every time (especially if you get to more than two cuts per cable)

There's actually a formula to use for figuring out how much the second cut should be, I just don't remember it though.

The article for the 12 foot stressed dish is in the ARRL handbook PDF I included in a previous post (post #9) the article is page 19-35. if you like all of the space communications data in it, becoming an ARRL member might give a lot more access to "interesting" stuff

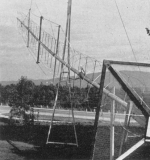

for the wullenweber array

Thanks

Joel

The first is that the velocity factor is a rough planning factor, it varies a lot, from roll to roll and according to some, foot by foot.

One of your points did open an old can of worms in my head.... some people really like measuring things based on resonant frequency, I have to assume because they want to control SWR or dont have better test equipment for other tests... The other way of measuring is "phasing" ie 90 degrees at 1.5 Ghz or something, this is good if you want to put something into quadrature to make a measurement.... The best (to me) idea is to use the actual time delay of a line, this is how they (them?) make wideband phased arrays, the swr and everything else will be off, but wide-banding things is sometimes more important... If you look at the wullenweber description, it was supposed to work from 1 Mhz to 30 Mhz with very high accuracy.... measuring and cutting things for SWR or Phase delay just wouldn't work (too broadband).

The part about your post that will get most people annoyed, is that after measuring the cable with the connectors on, and you need to cut it, you have to take the connector off, cut it, and (in my case) re-install the same connector, if you are using N connectors there is a rubber gasket that breaks when you put it on the first time, so you loose a little waterproofing when it's redone, but it would be ridiculous

s to use a new connector every time (especially if you get to more than two cuts per cable)

There's actually a formula to use for figuring out how much the second cut should be, I just don't remember it though.

The article for the 12 foot stressed dish is in the ARRL handbook PDF I included in a previous post (post #9) the article is page 19-35. if you like all of the space communications data in it, becoming an ARRL member might give a lot more access to "interesting" stuff

for the wullenweber array

Thanks

Joel

Last edited: