I decided, instead of buying one, I am going to build one.......

I am a Licensed Ham, KD5TPY, in Arkansas, and have some knowledge of antenna construction. I went through the formulas and here is what I intend (I hope that a antenna expert will correct me if I miss something):

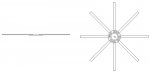

Cone Component:

Since this antenna will be used with a scanner and I have no real interest in frequencies below 136mhz and due to the length of the materials that I will make the cone radials - 48"x1/8"1/2" aluminum flat stock - each cone element will be 23" long - by the formulas, the lowest freq that the antenna will receive will be 127mhz.

The diameter of the base of the cone will also be 23", with 8 total cone radials.

I will attach each cone radial to a 3"diameter x 1/8" disc with two 1/8" aluminum pop rivets via a 1” flap on each radial. I will drill a 3/8” hole in the center of the disc. On the underside of this disc I will attach a PL-259 connector. The center connector will have a 1” X1/8” copper wire soldered, insulated from the cone plate via a 3/8” x 1/2” rubber grommet.

Next, there will be a 3”x1/4” plastic/phenolic insulation disc.

Disc Component:

The disc component of the antenna will consist of a 3” diameter x 1/8” aluminum disc with eight 7 1/2” x 1/8” x 1/2” aluminum flat stock radials attached to the disc with 1/8” pop rivets. The total final diameter of the Disc Component (as per the formulas) is 16”. The center conductor of the PL-259 will pass through a center hole in the disc and attached to the Disc Component via a 1/8” screw.

Finally, there will be another 3”x1/4” plastic/phenolic insulation disc.

The antenna will be held together with four 1/4” bolts passing through the top cone disc, the first insulator disc, the Disc Component and the top insulator disc, insulated from the Disc Component.

Questions for the experts:

Will the antenna work as commercially available Discone Antennas? Would the 1/2” flat stock work in the same way as aluminum rod?

I am a Licensed Ham, KD5TPY, in Arkansas, and have some knowledge of antenna construction. I went through the formulas and here is what I intend (I hope that a antenna expert will correct me if I miss something):

Cone Component:

Since this antenna will be used with a scanner and I have no real interest in frequencies below 136mhz and due to the length of the materials that I will make the cone radials - 48"x1/8"1/2" aluminum flat stock - each cone element will be 23" long - by the formulas, the lowest freq that the antenna will receive will be 127mhz.

The diameter of the base of the cone will also be 23", with 8 total cone radials.

I will attach each cone radial to a 3"diameter x 1/8" disc with two 1/8" aluminum pop rivets via a 1” flap on each radial. I will drill a 3/8” hole in the center of the disc. On the underside of this disc I will attach a PL-259 connector. The center connector will have a 1” X1/8” copper wire soldered, insulated from the cone plate via a 3/8” x 1/2” rubber grommet.

Next, there will be a 3”x1/4” plastic/phenolic insulation disc.

Disc Component:

The disc component of the antenna will consist of a 3” diameter x 1/8” aluminum disc with eight 7 1/2” x 1/8” x 1/2” aluminum flat stock radials attached to the disc with 1/8” pop rivets. The total final diameter of the Disc Component (as per the formulas) is 16”. The center conductor of the PL-259 will pass through a center hole in the disc and attached to the Disc Component via a 1/8” screw.

Finally, there will be another 3”x1/4” plastic/phenolic insulation disc.

The antenna will be held together with four 1/4” bolts passing through the top cone disc, the first insulator disc, the Disc Component and the top insulator disc, insulated from the Disc Component.

Questions for the experts:

Will the antenna work as commercially available Discone Antennas? Would the 1/2” flat stock work in the same way as aluminum rod?