CanesFan95

Analog already is interoperable.

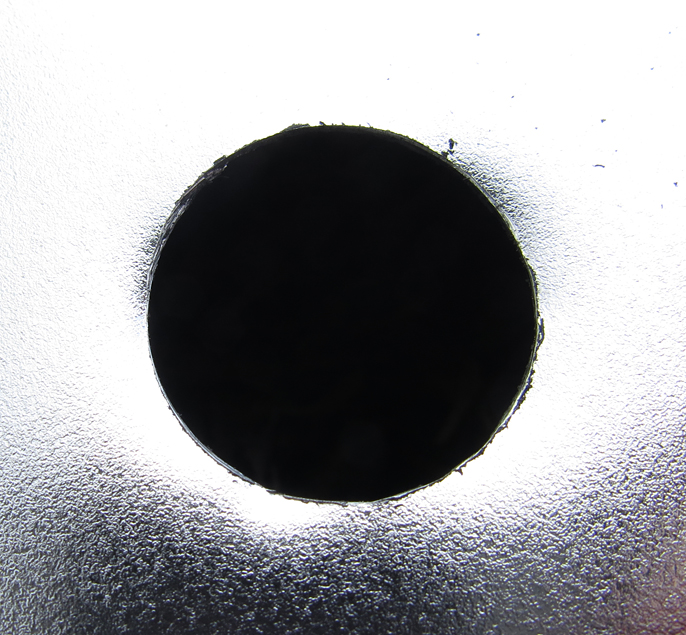

Here's a couple shots of the scrap.

They're expensive because they are the RIGHT thing to use. It's the difference between using a hexagonal die crimp tool for RF connectors like Mini-UHF, N-type, etc, and using a pair of 2 dollar slip-joint pliers. Yes, the 2-dollar pliers will work, but not very well.

Ever try to slice raw meat with a table knife? FWOMPT

While I do appreciate everyone's input about what drill bit to use, the DeWalt performed like a champ. It was actually very smooth and did not wobble or walk at all. The cut was quick and felt as easy as butter. Seriously.

It does tend to punch through though, so I might not want to use this for a roof install. But for the trunk, it is going to work just fine. The NMO mount looks like there is some wiggle room in the diameter as though the hole was just a bit too wide. But those are very close-up shots and it's hard to hold it exactly in place with one hand while snapping the photo.

Regardless, the mount still attached firmly barehanded with no problem, without a wrench.

The NMO hole saw is not designed to cut through anything any thicker than an auto body panel.

Sorry. I fat fingered the reply option on my phone. It's fixed, sir.....It would be nice if everyone would remember to DELETE the images when they quote a post...

Back-in-the-day when I was doing 2-way radio installs, I used a 3/4" Greenleaf hole punch. Drill a 3/8" hole and insert the punch bolt then screw on the other half. Of course this requires access to both sides of the metal but it will produce neat, clean and exact size holes without paint scratches if you don't use a conduit punch.

Can you remove it?Yes, the DeWalt drill bit comes with the spring on it.

Can you remove it?

Sent from my SM-T350 using Tapatalk